What are the main structural components of CNC machining centers?

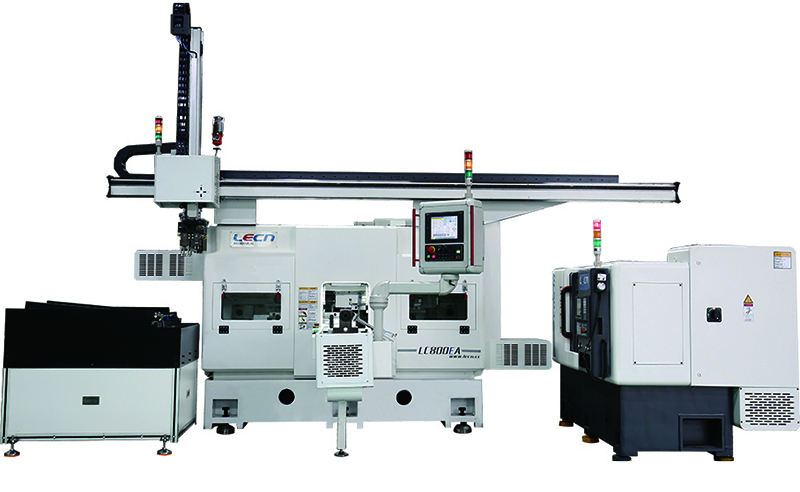

In common CNC machining centers, there is a division between vertical and horizontal types. Although they share similar external structures, overall, CNC machining centers are primarily composed of the following major parts.

1. Base Components

This forms the foundational structure, comprising the bed, columns, and worktable. It serves as the fundamental component of CNC machining centers, mostly constructed from cast iron. During operation, CNC machining centers must withstand static loads as well as dynamic cutting loads. Therefore, high rigidity is required for the bed casting, making it the most crucial component determining the quality of CNC machie.

2. Spindle Components

Consisting of the spindle box, spindle motor, spindle, and spindle bearings. Actions such as start, stop, and speed variation of the spindle are controlled by the numerical control (NC) system. It participates in cutting motion by holding the cutting tool mounted on it, serving as the power output component for machining. The spindle is a critical part of CNC machining centers, and the quality of its structure significantly impacts the performance of the CNC machining center, determining machining accuracy and stability.

3. Numerical Control System

The numerical control system of CNC machining centers comprises NC devices, programmable logic controllers (PLCs), servo drive systems, and operator panels. They serve as the control center for executing sequence control actions and completing operation processes during machining. The NC device is a position control system that processes input information, performs interpolation operations, obtains ideal motion trajectory information, and then outputs it to the executive components to produce the required workpieces. The servo system converts signals from the NC device into motion of the machine tool moving parts. Its performance is one of the main factors determining machining accuracy, surface quality, and production efficiency. CNC machining centers commonly adopt three control methods: open-loop, closed-loop, and hybrid.

4. Automatic Tool Change System

Comprising tool magazines, robotic arms, drive mechanisms, etc. During machining, when a tool change is required, the CNC system issues instructions for the robotic arm (or through other means) to retrieve the tool from the tool magazine and place it into the spindle hole. It addresses the task of automatic storage selection, handling, and exchange of tools between consecutive machining processes after the workpiece is clamped once. The tool magazine (tool disc) is a device for storing all the tools used in the machining process. Tool magazines come in disc-shaped and chain-type varieties, with capacities ranging from a few to dozens of tools. The structure of the tool arm varies depending on the relative position and structure of the tool magazine and spindle, such as single-arm and double-arm styles. Some CNC machining centers do not use tool arms but instead rely on the movement of the spindle box or tool magazine for tool changes.

5. Auxiliary Devices

Including lubrication, cooling, chip removal, protection, hydraulic, pneumatic, and detection systems. Although auxiliary systems do not directly participate in cutting motion, they play a crucial role in ensuring the machining efficiency, accuracy, and reliability of CNC machining centers, making them indispensable components.

- Previous: None

- Next: None