Mastering Induction Hardening Equipment: Unleashing Unmatched Performance

In the realm of cutting-edge engineering, induction hardening equipment stands as a pivotal tool, revolutionizing the way we enhance material strength and durability. At TY INDUCTION, we pride ourselves on providing industry-leading solutions that transcend the ordinary. In this comprehensive guide, we delve into the intricacies of induction hardening equipment, unlocking its potential for superior results.

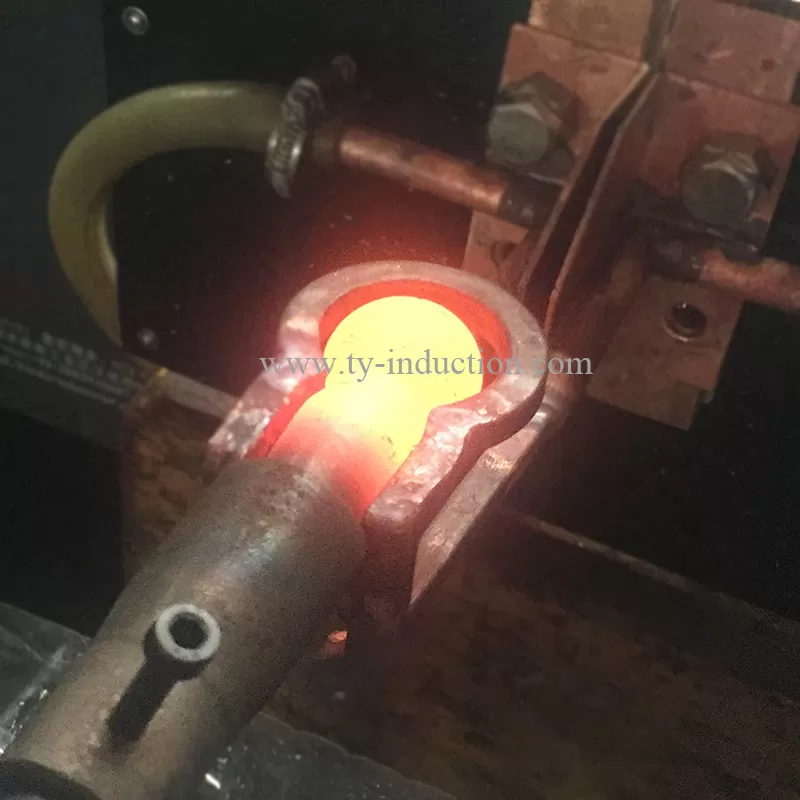

Induction hardening is a specialized heat treatment process that involves the use of electromagnetic induction to selectively harden specific areas of a metal component. This method offers unparalleled precision, ensuring that only targeted regions undergo the transformation, leaving the rest unaffected. This precision sets induction hardening apart, making it a preferred choice for applications where both hardness and flexibility are crucial.

The Advantages of Induction Hardening Equipment

Precision and Control

In the competitive landscape of modern engineering, precision is paramount. Induction hardening equipment empowers engineers with meticulous control over the hardening process. The ability to selectively target areas for hardening ensures that the desired mechanical properties are achieved without compromising the overall integrity of the component.

Rapid Heating and Cooling

Time is money in any industrial operation. Induction hardening equipment boasts rapid heating and cooling cycles, significantly reducing processing times. This efficiency not only enhances productivity but also contributes to energy savings, aligning with the global push towards sustainable manufacturing practices.

Consistency in Results

Consistency is the hallmark of quality, and induction hardening equipment excels in delivering uniform results. Whether treating small batches or large production runs, the technology ensures that each component undergoes the same rigorously controlled hardening process, guaranteeing consistent mechanical properties.

Applications Across Industries

Automotive Engineering

In the automotive sector, where components undergo extreme stress and wear, induction hardening is a game-changer. From crankshafts to camshafts, the technology ensures that critical engine components withstand the rigors of operation, extending the lifespan of automotive systems.

Aerospace Innovations

The aerospace industry demands materials with exceptional strength-to-weight ratios. Induction hardening equipment caters to this need, providing a means to strengthen components without adding unnecessary weight, thus contributing to the development of more fuel-efficient and high-performance aircraft.

Tool and Die Manufacturing

Precision is non-negotiable in tool and die manufacturing. Induction hardening equipment becomes an indispensable ally in this field, enabling the creation of robust tools with hardened surfaces that resist wear and deformation, ultimately extending tool life and improving overall efficiency.

Choosing the Right Induction Hardening Equipment

Power and Frequency Considerations

Selecting the appropriate power and frequency for induction hardening is critical. Higher frequencies are ideal for smaller components, offering precise control, while lower frequencies penetrate deeper, making them suitable for larger parts. Our experts we guide you in choosing the optimal parameters for your specific application.

Coil Design and Configuration

The design and configuration of the induction coil play a crucial role in the efficiency of the hardening process. Our state-of-the-art equipment comes with customizable coil options, ensuring adaptability to diverse component geometries and sizes.

Integration with Automation

In the era of smart manufacturing, seamless integration with automation systems is a necessity. Our induction hardening equipment is designed with Industry 4.0 principles in mind, facilitating connectivity and data exchange for a fully optimized and digitally controlled manufacturing environment.

Conclusion

In the dynamic landscape of industrial processes, induction hardening equipment emerges as a beacon of innovation, offering precision, efficiency, and consistency in material hardening. As Induction Hardening Company, we stand at the forefront of delivering cutting-edge solutions that redefine industry standards. Elevate your engineering prowess with our state-of-the-art induction hardening equipment and embrace a future where durability meets precision.