High Quality Tube Shoulder Making Machine vs Standard Models: Which Wins?

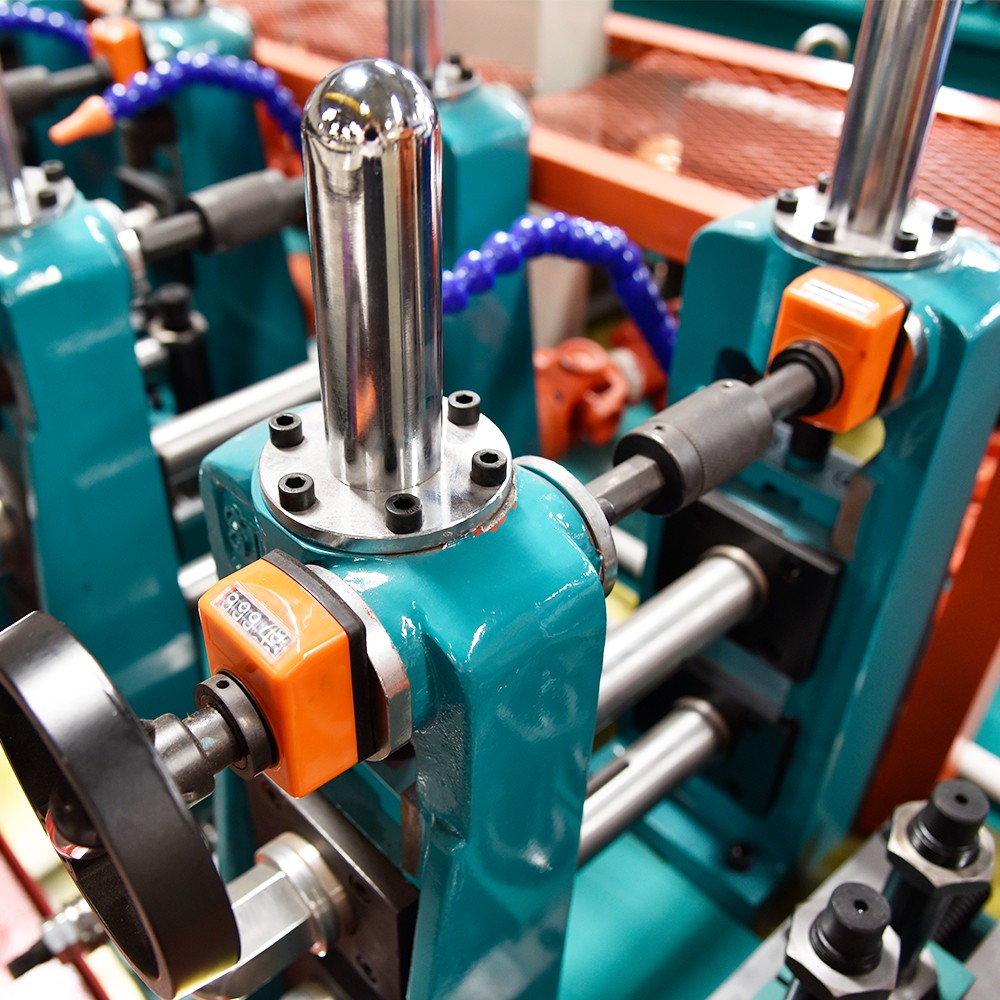

Understanding Tube Shoulder Making Machines

Tube shoulder making machines are essential in various industries, particularly in construction, automotive, and furniture manufacturing. These machines create shoulder components that enhance the structural integrity and aesthetics of tubes. When selecting a machine for production, businesses typically face a decision between high-quality models and standard options.High-Quality Tube Shoulder Making Machines: Features and Advantages

High-quality tube shoulder making machines are engineered with precision and durability in mind. Key features of these models often include:1. **Advanced Technology**: High-quality machines are equipped with state-of-the-art technology that ensures accurate shaping and cutting. This leads to a higher yield of products with minimal waste.2. **Improved Efficiency**: These models typically operate at faster speeds while maintaining consistent quality, which significantly reduces production time. 3. **Production Flexibility**: High-quality machines often offer more flexibility in terms of tube sizes and shapes. This adaptability allows businesses to cater to a wider range of customer needs.4. **Lower Maintenance Costs**: While the initial investment may be higher, high-quality machines usually settle into a lower cost of ownership over time. They require less frequent repairs and parts replacements, which translates into long-term savings.5. **Enhanced Safety Features**: With advanced safety protocols and features, high-quality machines minimize the risk of accidents during operations.Standard Tube Shoulder Making Machines: Pros and Cons

Standard tube shoulder making machines, on the other hand, present an appealing option for companies with limited budgets. Their characteristics include:1. **Lower Initial Cost**: The most significant advantage is the affordability of standard models, making them an attractive choice for startups and smaller businesses.2. **Simplicity of Use**: Many standard machines are designed with user-friendly features, allowing operators to get up to speed quickly.3. **Basic Functionality**: Standard models possess reliable capabilities for basic shoulder-making requirements but may lack the advanced features found in high-quality machines.However, there are notable downsides:1. **Limited Customization**: Standard models often come with fewer options for customization, which can limit production capabilities.2. **Higher Long-Term Costs**: Although the initial investment is lower, the frequency of repairs and parts replacement can increase the overall cost of ownership.3. **Lower Output Quality**: These machines may not deliver the same level of precision and finish as high-quality counterparts, potentially affecting the final product's marketability.Making the Right Decision

Choosing between high-quality tube shoulder making machines and standard models largely depends on various factors, including budget constraints, production requirements, and long-term business goals. Businesses focused on expanding their offerings, seeking higher efficiency, and aiming for better-quality products may find investing in high-quality machines to be more advantageous in the long run. Conversely, companies starting with limited resources might initially benefit from standard models to keep costs manageable.Regardless of the choice, it’s vital for decision-makers to analyze the specific needs of their operations and align them with the features of the machinery available in the market.Conclusion

Ultimately, the battle between high-quality tube shoulder making machines and standard models is nuanced and driven by individual business needs. As companies step into a competitive marketplace, understanding the strengths and weaknesses of each option can illuminate the path forward. For further guidance or personalized recommendations, contact us to discuss how we can assist you in making the best machinery decision for your production needs.For more information, please visit High Quality Tube Shoulder Making Machine, injection moulding machine vertical, tube shoulder making machine factory.

Recommended article:How to Select the Best Tube Shoulder Manufacturing Machine?

Understanding the Pricing Factors of Portable Pipe Cutting Machines

Unlocking Precision and Efficiency: How Fiber Laser Cutting Machines Work

Air-Cooled Screw Condensing Units

What Is an Excavator Vs Backhoe?

Plasma Cutter Safety: Best Practices and Tips for Safe Operation

Factors to Consider for Efficient Double Head CNC Lathe OperationsRecommended article:

Understanding the Lithium Battery Module Pack Assembly Line

What are Metal Shredders and How Do They Work?

Do you know the advantages of lintel making machine

What does a bucking unit do?

How to Choose the Right Rolling Machine?

What to Consider When Purchasing a Compressor?

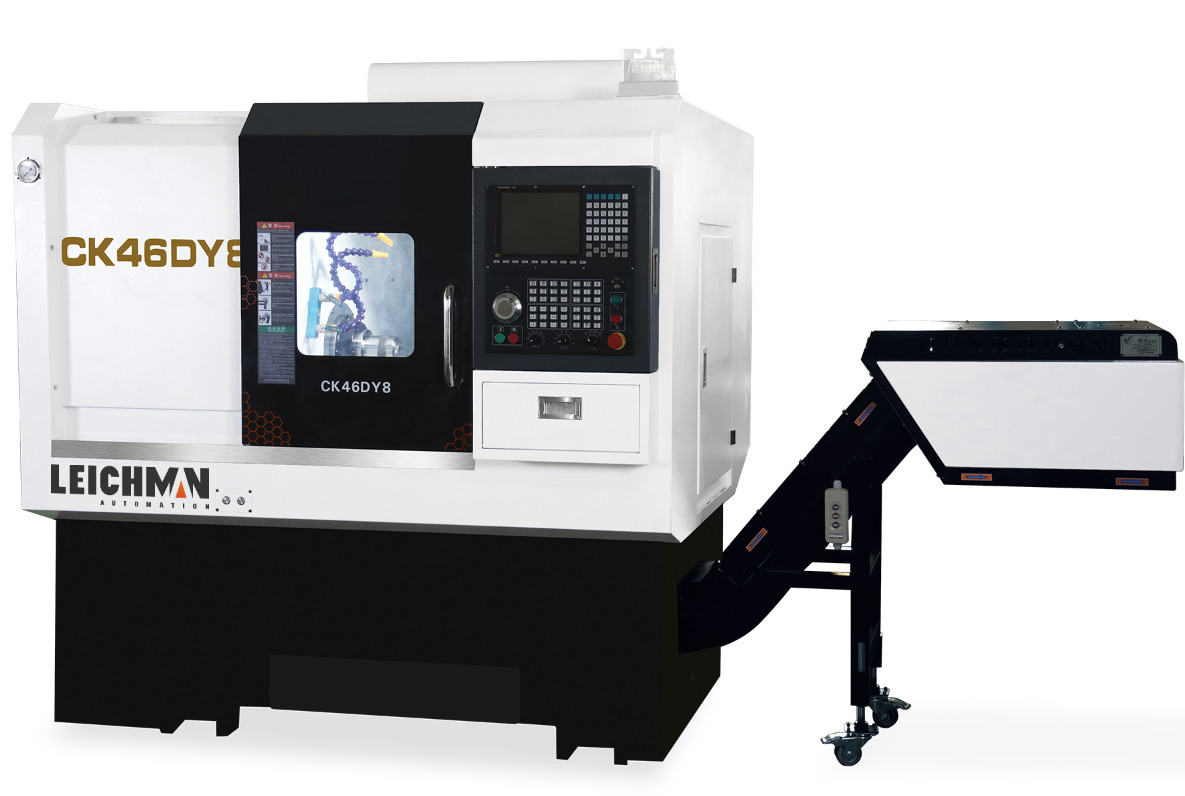

What is CNC lathe machine?