Double Sided Coatings: Boost Durability & Cut Costs Today!

If you are looking for more details, kindly visit Litong.

Understanding Double Sided Coatings

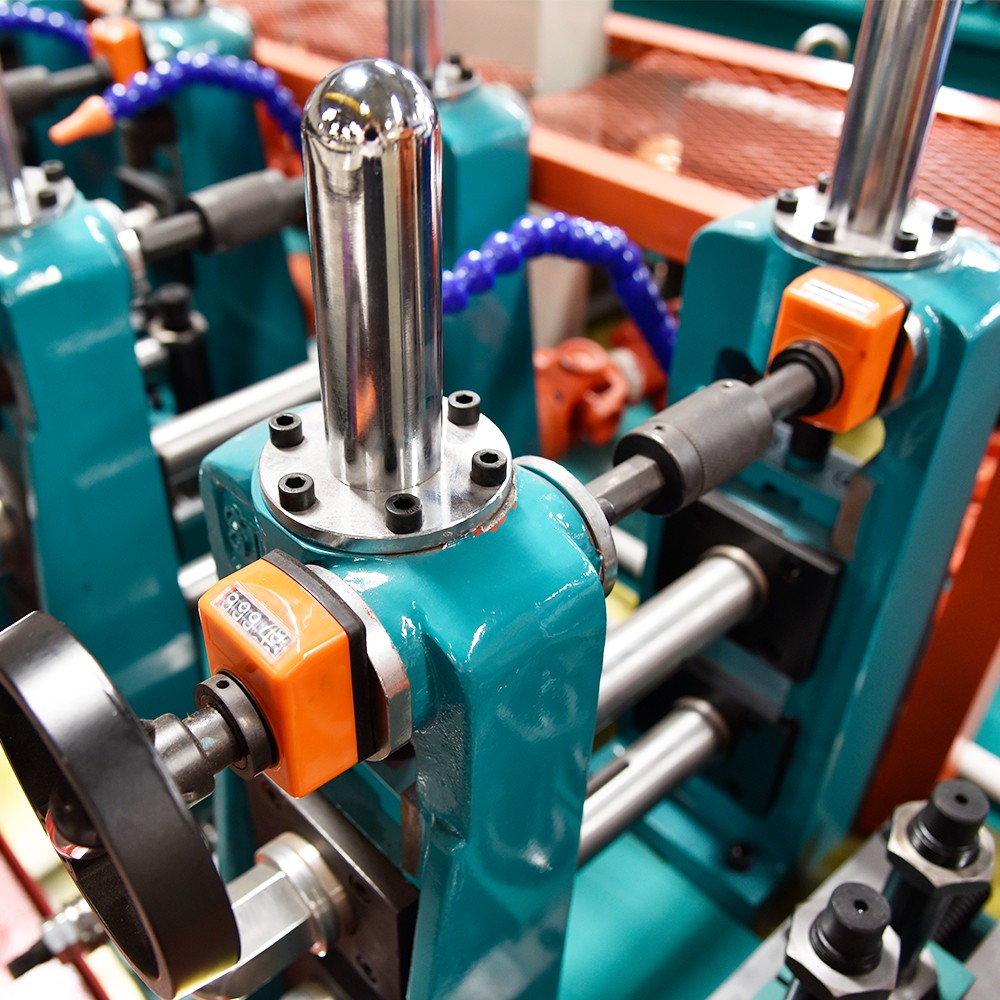

Double sided coatings represent a revolutionary approach to enhancing the performance and longevity of various materials, particularly in industries such as manufacturing, automotive, and construction. This innovative technology involves applying a protective layer on both sides of a substrate, significantly boosting its durability against wear and tear, corrosion, and other environmental factors. The key advantage of these coatings is their ability to offer a more comprehensive protective solution, which ultimately translates to a longer lifespan for the products in question.Benefits of Double Sided Coatings

One of the most compelling benefits of double sided coatings is their enhanced durability. By providing protection on both sides, these coatings mitigate the risk of damage from multiple angles, making them ideal for use in environments that are prone to harsh conditions. This dual protection significantly reduces the likelihood of scratches, dents, or corrosion, ensuring that products maintain their integrity and performance over time.Moreover, double sided coatings often lead to cost savings in the long run. While the initial investment may be higher than single-sided alternatives, the extended lifespan and reduced maintenance requirements result in lower overall costs. Businesses can save on replacement expenses, spare parts, and labor associated with repairs. This financial advantage makes double sided coatings a smart choice for many industries seeking both performance and cost-effectiveness.Applications Across Industries

The versatility of double sided coatings makes them applicable in a multitude of industries. For instance, in the automotive sector, these coatings are often used on exterior parts to protect against rust and paint degradation caused by environmental factors, such as road salt and UV exposure. Similarly, in the construction industry, they provide a protective barrier for structural materials, prolonging their lifespan and reducing the need for costly repairs.In the manufacturing realm, double sided coatings enhance the durability of tools and machinery, reducing downtime associated with maintenance and replacing damaged parts. By investing in products with these coatings, industries can improve operational efficiency while minimizing disruptions caused by unforeseen equipment failures.Choosing the Right Double Sided Coating

Selecting the appropriate double sided coating requires careful consideration of several factors, including the specific application, environmental conditions, and desired performance characteristics. It is essential to assess the substrate material and determine whether the coating is compatible, as this can affect adhesion and overall effectiveness. Additionally, various coating materials—such as polymers, metals, and composites—offer different benefits and levels of protection.For those unsure about which specific coating will best suit their needs, consulting with coating professionals or manufacturers can provide valuable insights. Experts in the field can recommend the most suitable options based on industry standards, production requirements, and cost considerations.Conclusion: Elevate Your Game with Double Sided Coatings

In summary, double sided coatings are transforming the way industries approach durability and cost management. By investing in this advanced protective technology, organizations can not only enhance the lifespan of their products but also reduce costs associated with repairs and replacements. If your business is looking to improve efficiency and sustainability, double sided coatings may be the ideal solution.For more information and to explore the range of double sided coatings available, please don’t hesitate to contact us.If you are looking for more details, kindly visit our website.

Recommended article:How Does a Double Sides Coatings Line Work?

Choosing the Right Bottle Bagging Machine for Your Packaging Needs

The Laser Cutter Revolution: Transforming Design and Manufacturing

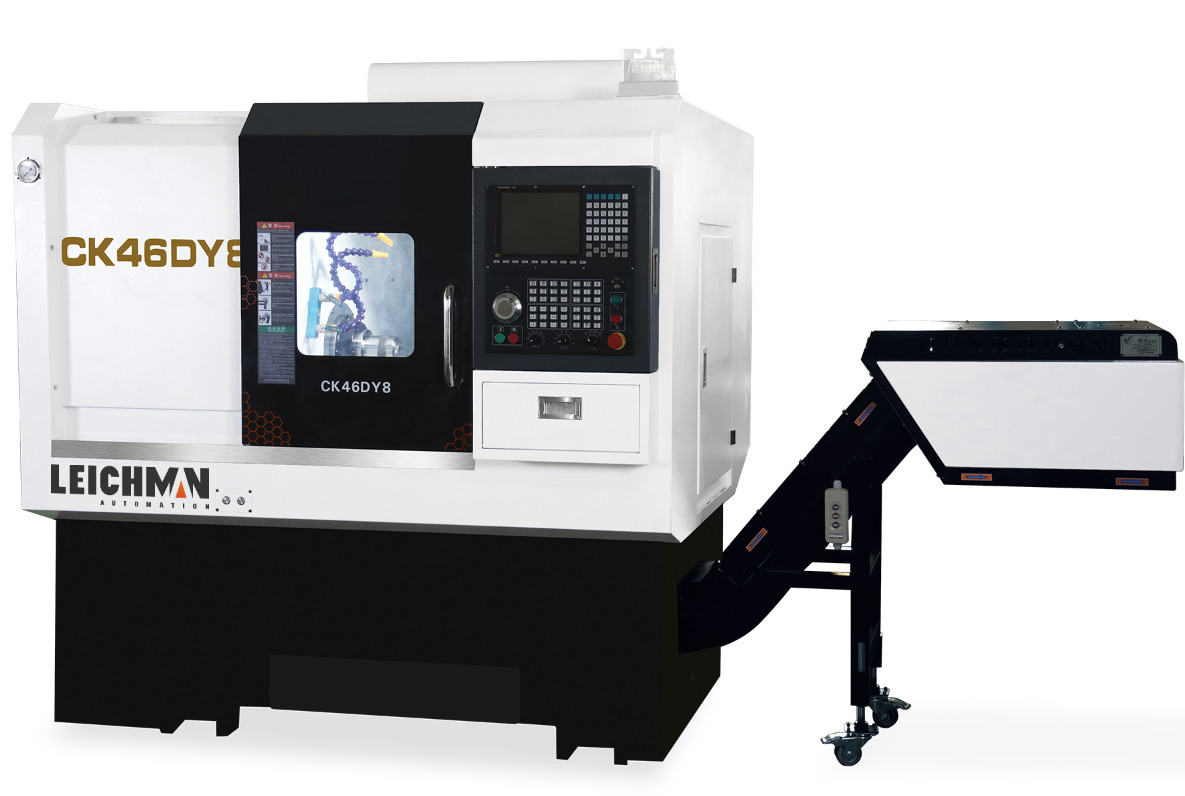

Understanding the Basics of CNC Lathe Machines: Operation and Applications

Enhancing Efficiency and Precision: The Advantages of CNC Pipe Threading Lathes

Understanding the Pricing Factors of Portable Pipe Cutting Machines

Unlocking Precision and Efficiency: How Fiber Laser Cutting Machines Work

For more Double Sides Coatings Lineinformation, please contact us. We will provide professional answers.

Recommended article:Air-Cooled Screw Condensing Units

What Is an Excavator Vs Backhoe?

Plasma Cutter Safety: Best Practices and Tips for Safe Operation

Factors to Consider for Efficient Double Head CNC Lathe Operations

Understanding the Lithium Battery Module Pack Assembly Line

What are Metal Shredders and How Do They Work?

Do you know the advantages of lintel making machine